PetalC and Petal17 – what has changed with Gall Thomson’s latest Marine Breakaway Coupling evolution

PetalC, the latest addition to Gall Thomson’s Petal Valve Marine Breakaway Coupling (MBC) range is hailed as a significant advancement in MBC technology, but how does it differ from Petal17, the established market leader?

The PetalC MBC has been designed to enhance protection of breakstuds during exceptional bending movements without affecting their axial load performance during normal operations. This is particularly important to operators using nipple hoses in applications such as FPSO with reels.

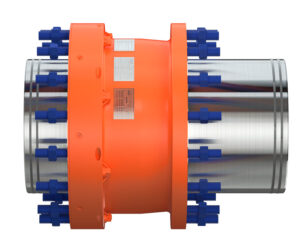

PetalC

Both ends of the PetalC fit within the nipples of the hoses. This reduces the MBC installed length by 60 per cent and enables the unique profile of PetalC to use the hose nipple construction to its advantage and reduce axial load by up to 30 per cent on the most critical breakstuds.

PetalC therefore does not require Transit Bolts during offshore operations, unless specifically requested by the operator. Transit Bolts clamp the MBC together so that the breakstuds are protected and therefore activation is disabled when the MBC is stored on the FPSO during hose loading operation. Transit Bolts must then be removed when the hose is deployed so that MBC protection is active during offshore operation.

When comparing the PetalC with the Petal17, it becomes immediately apparent that PetalC retains the same basic internal workings, which ensures minimal change management for any operator switching from one to the other.

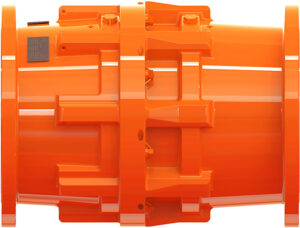

Petal17

The sealed sleeve bore design of Gall Thomson Petal Valve MBCs ensures internal mechanisms are protected, eliminating the risk of clogging and promoting low maintenance and long service life. Both PetalC and Petal17 have passive self-energised protection systems. Shut-off is powered by the energy of the flowing product acting on the Petal assembly. This means the unit does not rely on any external power source.

Extensive testing with an industry leading hose manufacturer and witnessed by Lloyds Register, reported “When subjected to high loads, the PetalC experiences 20 to 30 per cent less axial load at the most critical breakstuds when non-pressured and pressurised respectively when compared to Petal17.”

PetalC has subsequently been successfully utilised by operators across the world and is proving to deliver the solutions for which it was designed.

Petal17 came to market in 2017 and has been described as the most advanced protection against offshore oil spills in the world.

The CNC manufactured Petal Valves in Petal17 provide far greater precision than previous manufacturing techniques. Petal17 also offers the innovative Petal Valve locking mechanism as an optional extra, providing activation advantages where both low pressure and adverse weather conditions converge.

Petal17 is up to 20 per cent lighter than the previous Gall Thomson MBC range – which was already the lightest on the market and, working with the Gall Thomson Ultrafloat, it delivered positive buoyancy, even on activation.

Gall Thomson has nearly 50 years of successful field experience and a track record of more than 2,400 MBCs in service, some deployed in some of the harshest environments in the world.