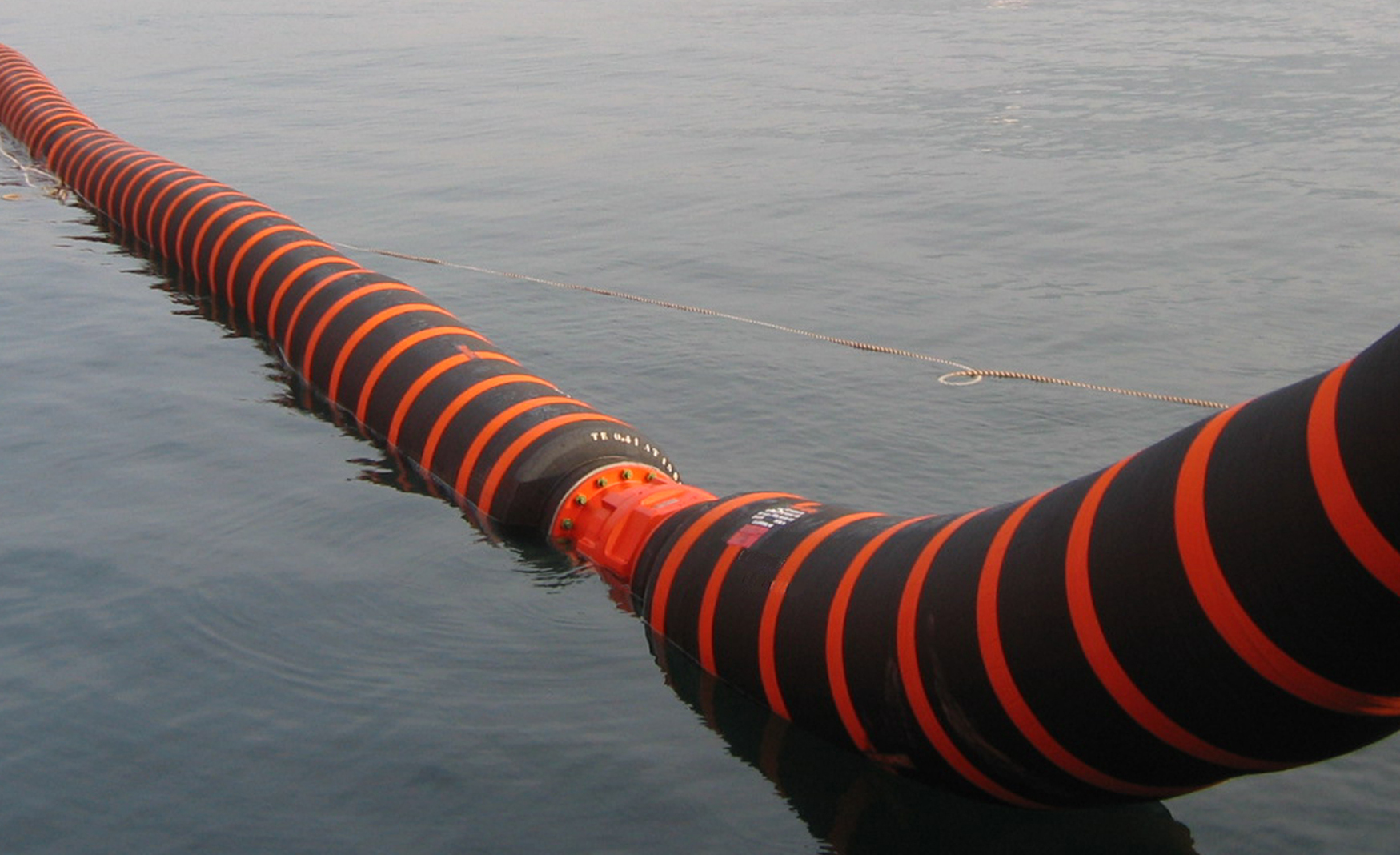

Petal Valve Marine Breakaway Couplings

This review is of the commonly used Gall Thomson Petal Valve Marine Breakaway Coupling (MBC).

Application

Hose offshore transfer of high viscosity media such as crude oil between Floating Production Storage and Offloading platforms (FPSOs) and tankers or between tankers or vessels.

Purpose

Gall Thomson Petal Valve offshore Marine Breakaway Couplings are designed to protect a transfer operation in an emergency.

This coupling will automatically activate due to either one of two ends of the line moving beyond a pre-defined distance or because of an unacceptable pressure surge.

Vessel displacement is where the vessel moves beyond the available distance offered by the transfer line. This scenario can occur due to the breaking of moorings in adverse weather conditions, equipment malfunction, human or procedural error.

Pressure surge is typically due to a malfunction of another component within the transfer line.

When the coupling is activated, the up and downstream flow is shut down by the closure of two Petal valves. The coupling separates and the hose string is no-longer constrained by connection.

Without an MBC, stress on the hose caused either by unacceptable movement or pressure surge can result in damage to hoses and other assets, potential injury, extended downtime and spill of media into the environment.

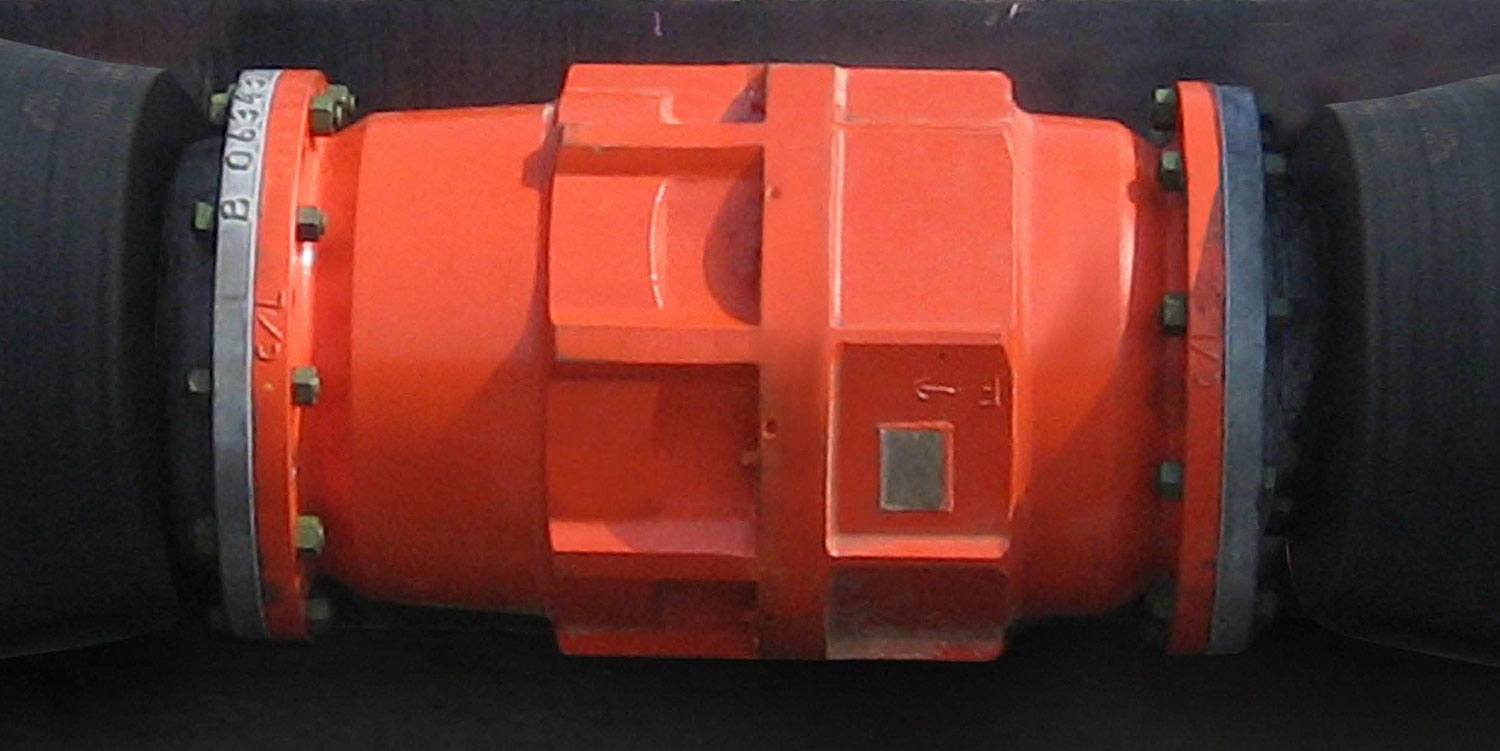

Product profile

Activation is provoked by breakstuds which are designed to split at pre-defined breakloads. The breakloads are determined at the specification stage.

Fully sealed sleeved bore, isolating the internal components of the device from the product flow, considerably reduces maintenance costs.

This MBC features sixteen petals in two assemblies of eight. On separation following an activation, the extreme tension in the hose string is relieved and the Petal Valves close and shut off product flow.

Valve closure is powered by the energy of the flowing product.

Closure of valves can be executed at a controlled rate on the upstream side or in both directions in the case of a bi-directional flow system. Controlled closure can prevent potential damage to associated equipment such as pumps, meters, expansion joints, hoses or gaskets.

The Gall Thomson Petal Valve MBC can also be specified to deliver instantaneous shutdown.

Available in nominal bore sizes of 6″ to 24″.

Typical operational applications

- Floating hose strings at Single Point Mooring (SPM) systems including Catenary Anchor Leg Mooring (CALM) buoy/Single Anchor Leg Mooring (SALM) buoy terminals.

- Underbuoy hose strings at Single Point Mooring (SPM) terminals.

- Floating hose strings installed at Floating Storage and Offloading (FSO) and Floating Production Storage and Offloading (FPSO) tankers.

- Reeled Floating or in-air/submerged catenary hose strings installed at Floating Storage and Offloading (FSO) and Floating Production Storage and Offloading (FPSO) tankers.

- Conventional Buoy Mooring (CBM)/Multi Buoy Mooring (MBM) submarine hose strings.

- Articulated Loading Platform in-air or submerged catenary hose strings.

- Subsea high pressure live crude flexibles.

- Well choke and kill emergency disconnect systems.

Typical media

Petal Valve MBCs are primarily designed for use with high viscous media such as crude oil or heavy fuel oil but are compatible with all hydrocarbons including liquid gases.

Performance

Gall Thomson Petal MBCs are proven as reliable and meet the status of Gall Thomson Field Verified.

Full, smooth and uninterrupted bore provides zero headloss, eliminating pressure drop during product transfer or the necessity to increase power at the pumps to maintain original design flow rate.

In the event of a breakout, the device will operate without any outside intervention by personnel or system. The MBC is therefore independent and not reliant on external or additional equipment that possesses additional reliability variables such as probability of performance or reliance on the fulfilment of indirect maintenance schedules.

This MBC is therefore completely self-contained with no outside power source required.

No human interaction is required to activate the MBC.

Valve closure speed can be altered in service without dismantling the unit.

Activation takes place due to linear overload or extreme internal pressure, providing surge protection.

The petal mechanism is designed so that therefore are no axles, shafts, hubs or bearings to seize.

Internals are sealed until an activation occurs. This prevents erosion and corrosion in normal pumping operations and seawater flushing. Clogging is also avoided. The MBC is therefore designed to maximise product life.

Low weight and compact design.

Fits between standard flanges at any recommended location in hose assembly.

Variable closure speed gives anti-shock shut down.

Dynamic parting loads can be varied to suit system.

Cost assessment

Additional costs – servicing

To ensure reliability of breakaway couplings, it is important to adhere to the recommended service schedule. If you currently don’t have an MBC in your transfer line but plan to fit one then expect to integrate its servicing into your maintenance schedule.

Based on normal operating conditions, Gall Thomson Petal Valve MBCs should be serviced every five years. Expected life is 20 years over three service life cycles.

Potential cost savings compared to alternatives

Because there are no complicated or high maintenance monitoring systems required, Gall Thomson Petal Valve MBCs offer the optimum solution in protecting hose transfer systems during high viscosity media operations.

Conclusion

Minimising risk for an operation and demonstrating due diligence in protecting the environment is an important objective for modern operations. Gall Thomson Petal Valve MBCs offer a cost-efficient proven protective solution for operations involved with the transfer of media in an offshore environment.

Further information from supplier: gallthomson.com